Table of Contents

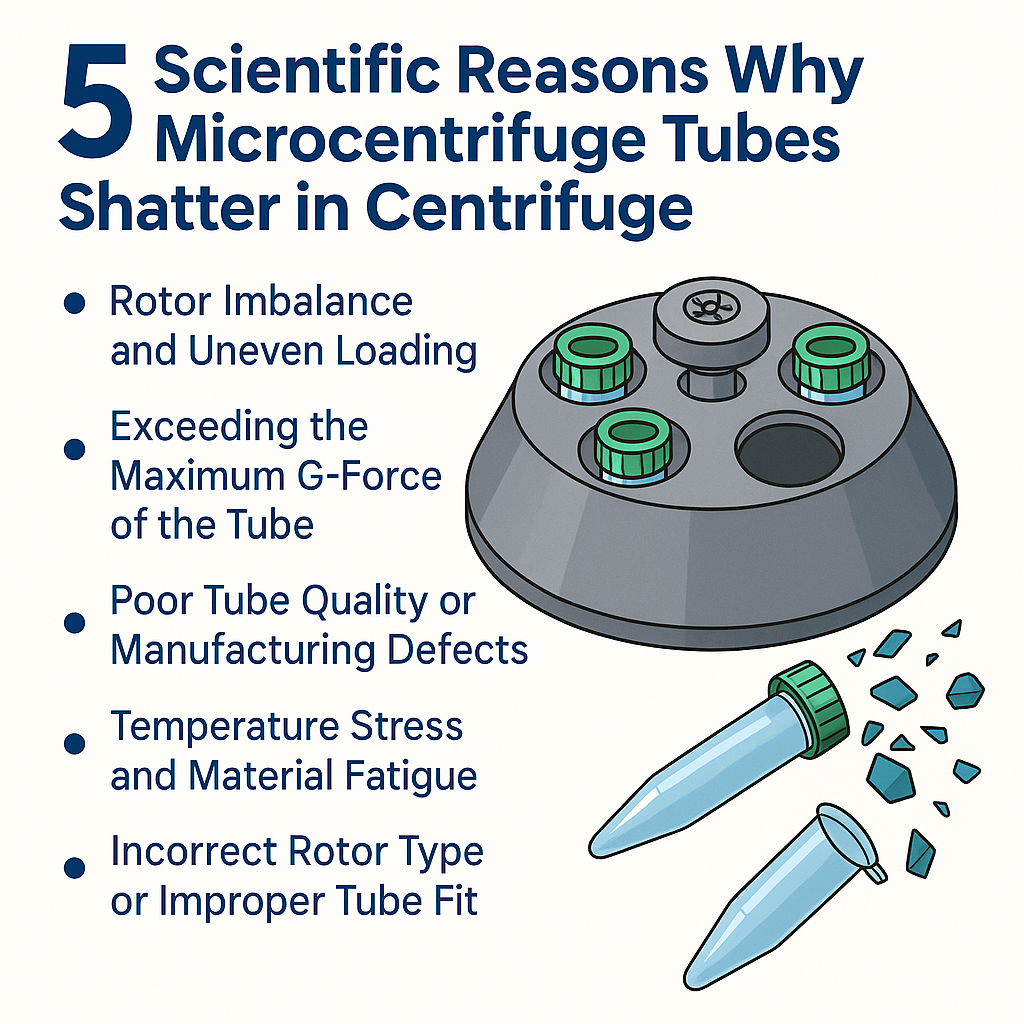

Microcentrifuge tubes are essential consumables in molecular biology, biochemistry, and clinical diagnostics. They are designed to withstand extreme centrifugal forces, but sometimes researchers experience a frustrating (and dangerous) issue: tubes shattering inside the centrifuge. This not only damages valuable samples but can also harm the equipment and compromise results.

In this article, we’ll break down the top 5 scientific reasons why microcentrifuge tubes shatter in centrifugation and explain how to prevent it.

1. Rotor Imbalance and Uneven Loading

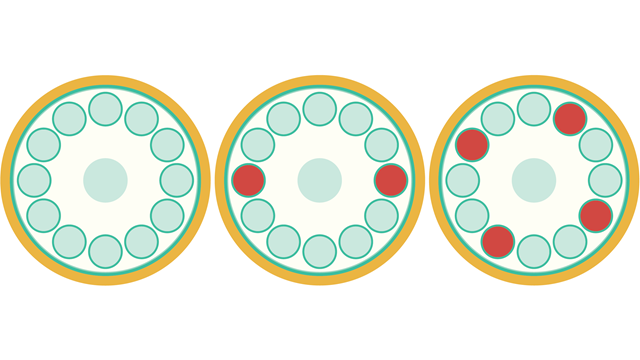

One of the most common causes of tube failure in a centrifuge is imbalance. If the rotor is not evenly loaded with tubes of equal weight and volume, the centrifugal force is distributed unevenly. This creates excessive stress on one side of the rotor and can lead to tube cracking or complete shattering.

- Always balance tubes by placing them opposite each other in the rotor.

- Ensure liquid volumes are equal to prevent weight discrepancies.

- For odd numbers of samples, use a balance tube filled with water or buffer.

Imbalance is a mechanical issue that can be prevented with careful loading, making it the first thing to check if tubes keep breaking.

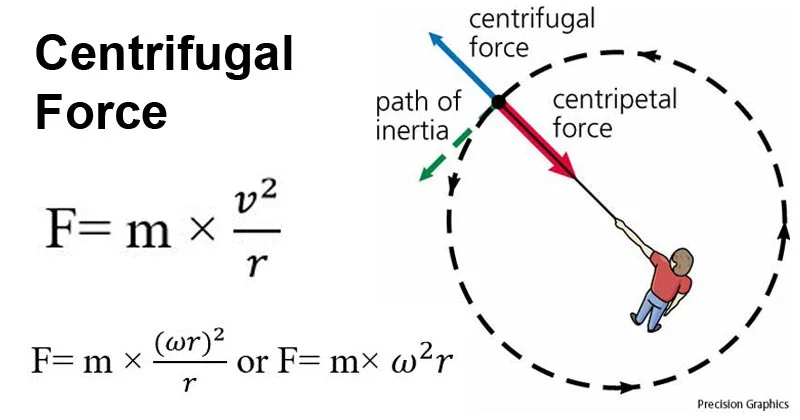

2. Exceeding the Maximum G-Force of the Tube

Every microcentrifuge tube is rated for a maximum centrifugal force (RCF or g-force). Standard polypropylene tubes typically tolerate up to 20,000 × g, while higher-quality ultracentrifuge tubes may withstand 60,000 × g or more.

If the centrifuge is set above the tube’s tolerance, the wall structure cannot withstand the stress and eventually shatters.

- Always check the manufacturer’s specifications for g-force limits.

- Do not confuse RPM with RCF (relative centrifugal force)—they are not the same.

- Use the RCF conversion formula:

RCF=1.118×10−5×r×(RPM)2RCF = 1.118 × 10^-5 × r × (RPM)^2RCF=1.118×10−5×r×(RPM)2

(where r = radius in cm)

Running tubes beyond their rated tolerance is one of the fastest ways to cause failure.

3. Poor Tube Quality or Manufacturing Defects

Not all microcentrifuge tubes are created equal. Low-grade plastics, thin walls, or poor molding can create weak points that fail under high g-forces. Even a small defect can lead to catastrophic breakage when the rotor reaches full speed.

Signs of poor-quality tubes include:

- Inconsistent wall thickness

- Visible seams or bubbles in the plastic

- Loose or poorly fitting caps

To prevent issues, source tubes from trusted suppliers that comply with ISO and CE standards. Choosing certified, high-quality lab disposables ensures safety, reproducibility, and protection of valuable samples.

4. Temperature Stress and Material Fatigue

Centrifugation often occurs under extreme temperature conditions—such as -20°C for nucleic acid extraction or 4°C for protein stability. Sudden shifts between freezing and high-speed centrifugation can create thermal stress, causing brittle plastic to crack.

In addition, repeated cycles of centrifugation weaken tube material over time, a process known as material fatigue.

Prevention tips:

- Use refrigerated centrifuges designed for temperature-sensitive applications.

- Avoid reusing tubes multiple times at high g-forces.

- Store tubes under recommended conditions to preserve integrity.

5. Incorrect Rotor Type or Improper Tube Fit

Not every tube is designed for every rotor. Using the wrong rotor type (e.g., swinging bucket instead of fixed angle) or forcing a tube into the wrong adapter can create structural stress points.

For example:

- A 15 mL conical tube in a rotor meant for microtubes may experience uneven pressure.

- Microtubes that don’t sit flush in the rotor can wobble and shatter.

Always ensure:

- The tube type matches the rotor specifications.

- Adapters are used for smaller volumes.

- Tubes are seated properly before centrifugation begins.

Bonus: Chemical Interactions

Sometimes overlooked, chemicals inside the tube can also weaken plastic. Harsh solvents (e.g., chloroform, phenol, or strong detergents) degrade polypropylene, making it more prone to cracking during centrifugation.

Conclusion

Microcentrifuge tubes are designed to handle extreme stress, but imbalances, excess g-force, poor tube quality, temperature shifts, and rotor mismatches can cause them to fail. By understanding these scientific causes and applying preventive steps, laboratories can protect valuable samples, extend equipment lifespan, and ensure safe centrifugation practices.

When sourcing microcentrifuge tubes, always choose suppliers who comply with ISO, CE, and FDA standards. A small investment in quality products can save thousands in equipment repairs and lost research time.